- info@tycoonit.in

- +91 0821-4266933

Our Services

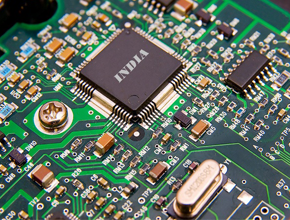

EMS Services + Solutions

We provider of complete manufacturing services ranging from Printed Circuit Assembly to Complete System Integration and Box Build.

- PCB Assembly Services

- PCB Assembly Capabilities

- Manufacturing Capabilities of PCB

- Engineering Design

- Manufacturing Solutions

- Sourcing Strengths

Highlights of PCB Assembly Services

- Expertise is in the assembly of high mix, high density printed circuit board assemblies.

- Tycoon IT offers PCB assembly of single or multi-layer flexible or rigid circuit boards.

- Tycoon IT support both high and low-mix assembly volumes that range from just a few prototype units to high volume production.

- PCB Assembly Manufacturing environment is fully satisfies the ESD compliance.

- Tycoon IT is capable to handle Complex PCB assembly requirements, by offering superior service to the customers for their immediate requirement.

PCB Assembly Capabilities

- Full turnkey(complete Box build with electronic, electromechanical components).

- Prototype and High volume Assembly.

- ROSH / Lead free PCB Assembly.

- BGA and Micro-BGA Capabilities.

- Through-Hole Assembly.

- Surface-Mount Assembly.

- Cable & wire Harnesses Assembly.

- Mechanical Assembly.

- Mixed Technology Assembly.

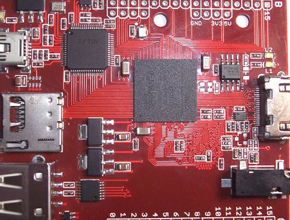

Manufacturing Capabilities of PCB Assembly

- Low-volume prototyping.

- Low-volume / high-mix.

- High-volume / low-mix.

- Build to order.

- Configure to order.

Engineering Design Services

Design services are offered in the area of component re-engineering for obsolescence, up gradation of designs, reliability engineering/ of products. .

Turnkey Manufacturing Solutions

In today's competitive manufacturing environment, delivering products securely and timely is more critical than ever. TYCOON IT delivers complete manufacturing services from PCB assembly (PCBA) to complex systems integration and configuration. We bring you advanced manufacturing solutions with expertise across a diverse product mix. You focus on your core business. We focus on reducing your costs, speeding your products to market and helping you gain a competitive edge.

This approach enables us to deliver highly competitive services in an increasingly complex industry with a diverse, competitive customer base. It also allows us to make fast, flexible decisions in response to changing market conditions. TYCOON IT delivers value and innovation to our original equipment manufacturer (OEM) customers.

Along with the facilities for manufacturing, we have customized lines for Box build, Integration, Testing, Burn In facility to offer OEM manufacturing of products

Sourcing Strengths

- Value & reliability engineering for new products.

- Turnkey projects – from material procurement to product shipment.

- Customized job work.

- Global sourcing .

- Verification of BOM.

- Drop-in / alternate parts for non-stocked and obsolete parts. .

- Approval from Customer for suggested parts.

- Process compatibility & Flow Charts .

- Equivalent RoHS parts for the projects with RoHS compliance.

Infrastructure & Facilities

- Production area of 4000sq feet ,with modern layout.

- Production floors separated in accordance to product categories, for easy

operation of machines, tooling and test equipments, and movement of men and material. - Total ESD Protected Area.

- 1 Line automatic assembly line in SMT.(Juki ).

- 2 Line assembly in PTH .

- 5 zone reflow oven .(EPS)

- 3 zone reflow oven .(EPS).

- 2 Wave soldering machine. (EPS) .

- IC Rework station. (HAKKO)

- Highly skilled soldering technicians.

- Capability to handle fine pitch, 0201, BGA, POP,QFN & All types.